For over 30 years, we have been delivering advanced solutions with an emphasis on performance, reliability, and long-term service life.

BOCO Pardubice machines, s.r.o. was established in 1994 with a clear goal – to deliver top-quality extrusion technology for the plastics and rubber industries. From the very beginning, the company has focused on continuous improvement and product innovation, supported by a strong internal team, in-house development, and close cooperation with clients and research institutions.

Thanks to this strategy, BOCO is now one of the leading European manufacturers of extrusion equipment and specialized components.

Our manufacturing and technological base is located in Holice near Pardubice. From here, we supply products and complete extrusion lines to customers in the Czech Republic, Slovakia, Germany, Austria, Poland, and other European countries.

We deliver reliable and durable extrusion technology. The foundation of our quality is attention to detail and individual approach to customer needs.

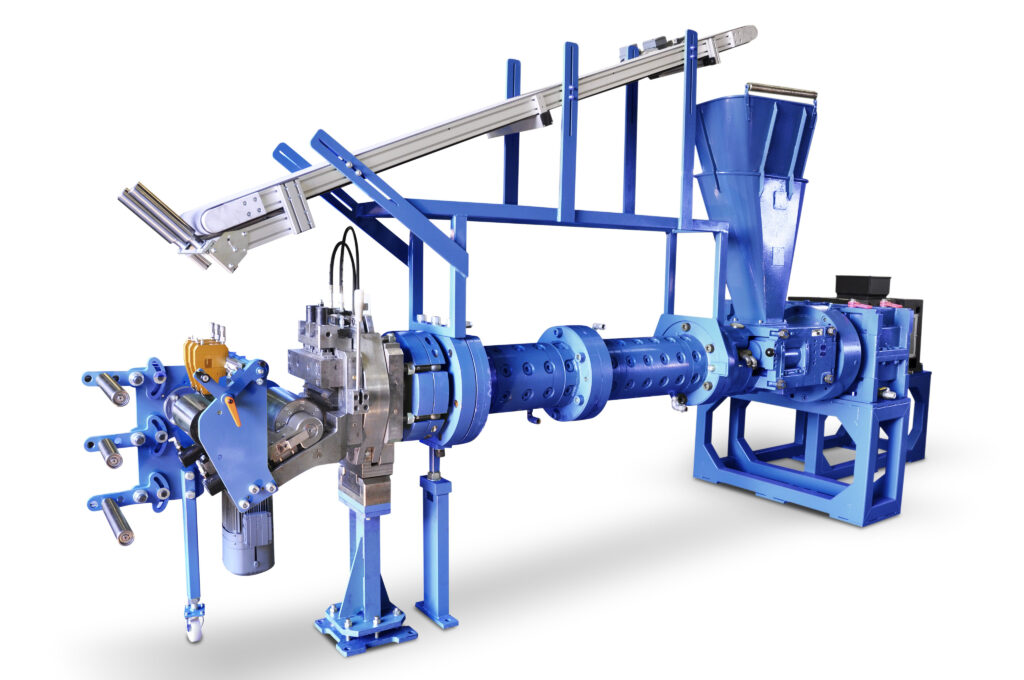

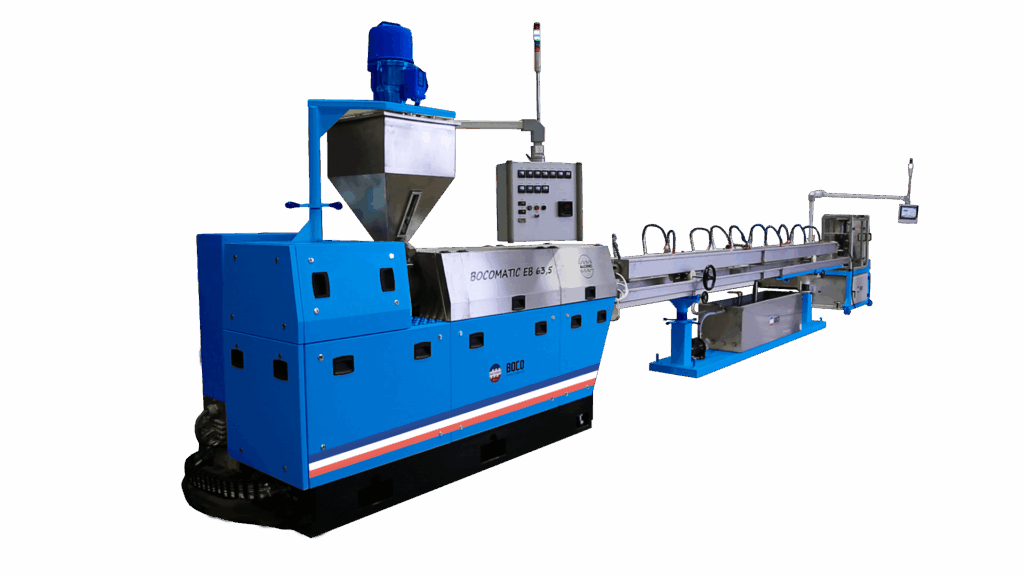

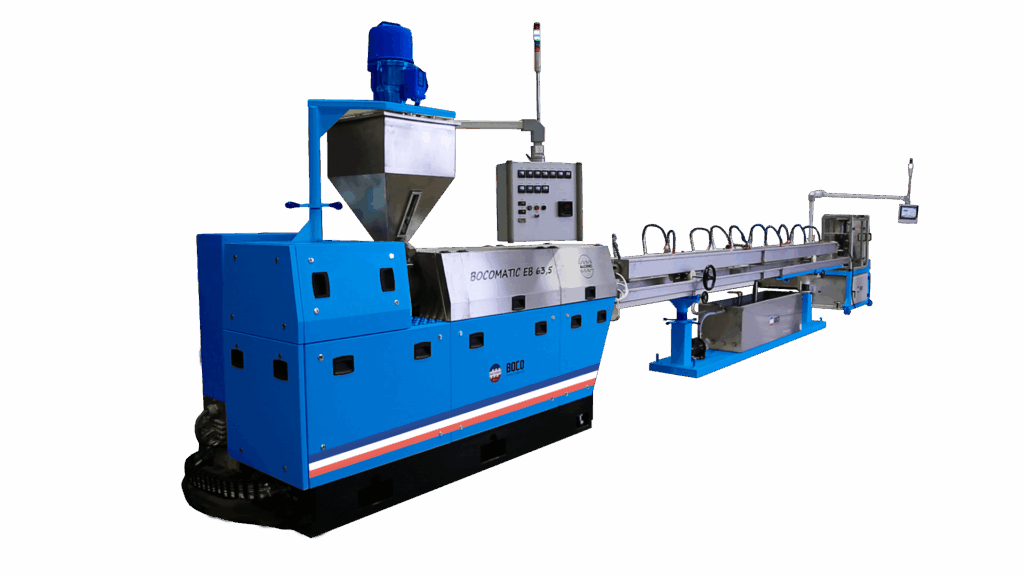

We design and manufacture complete production lines for plastics processing. Thanks to in-house development, we can flexibly respond to specific customer requirements and optimize production in line with practical demands. Barrels, screws, extruder heads and entire extrusion lines are part of our delivery.

BOCO extruders are designed for high performance and long service life. Their durability is guaranteed by robust design, choice of high-quality materials, precise production, and ongoing innovation. A wide range of diameters and configurations is available to suit various applications – from laboratory machines to large-scale industrial production.

Our extrusion lines are tailored to the customer’s specific needs and adapted to the required application. We supply lines for processing technical and soft plastics, recycled materials, silicone, or compounds. We also offer complete turnkey solutions, including upstream and downstream equipment.

BOCO supplies complete solutions for recycling and regulating production waste. These lines are designed for regranulation and reuse of production scrap and can be integrated into new or existing extrusion lines. The goal is to reduce material costs and optimize sustainability.

We specialize in both the production and renovation of screws and barrels for plastic and rubber processing. We focus on minimizing wear, ensuring high quality output and optimizing durability. All renovation work is carried out using high-precision equipment and hard surfacing techniques.

Thermal insulation covers help reduce heat loss in extrusion lines, leading to increased energy efficiency and improved operator safety. The covers are made to measure and adapted to the dimensions of your equipment.

We also offer standalone components for extrusion and recycling lines – such as dosing units, water baths, drying systems, granulators, haul-offs, and other downstream equipment. These parts can be included in custom-designed lines or integrated into existing setups to improve performance.

Our work is based on values, technical precision, and long-term cooperation with customers and industry partners.

Based on many years of experience in designing and producing extrusion machinery and components.

Close cooperation with research institutions and continuous product innovation.

We monitor the latest trends in the industry and apply modern technologies in production and development.

Our in-house team of technicians, consultants, and support staff is ready to help you with both technical design and implementation.